Mineral Resource Update 2021

2021 Mineral Resource Estimate Highlights

Vanadium One Iron completed a new mineral resource estimate in May 2021.

The updated resource incorporates results from the 2020 drill program which focused on defining the eastern extension of the North Zone as

well as some infill in the North Zone. This has resulted in an increase in the total Inferred Mineral Resource tonnage in the North Zone from 376 Mt to 809.1 Mt at 34.2% magnetite, an addition of 433 Mt or a 115%increase.

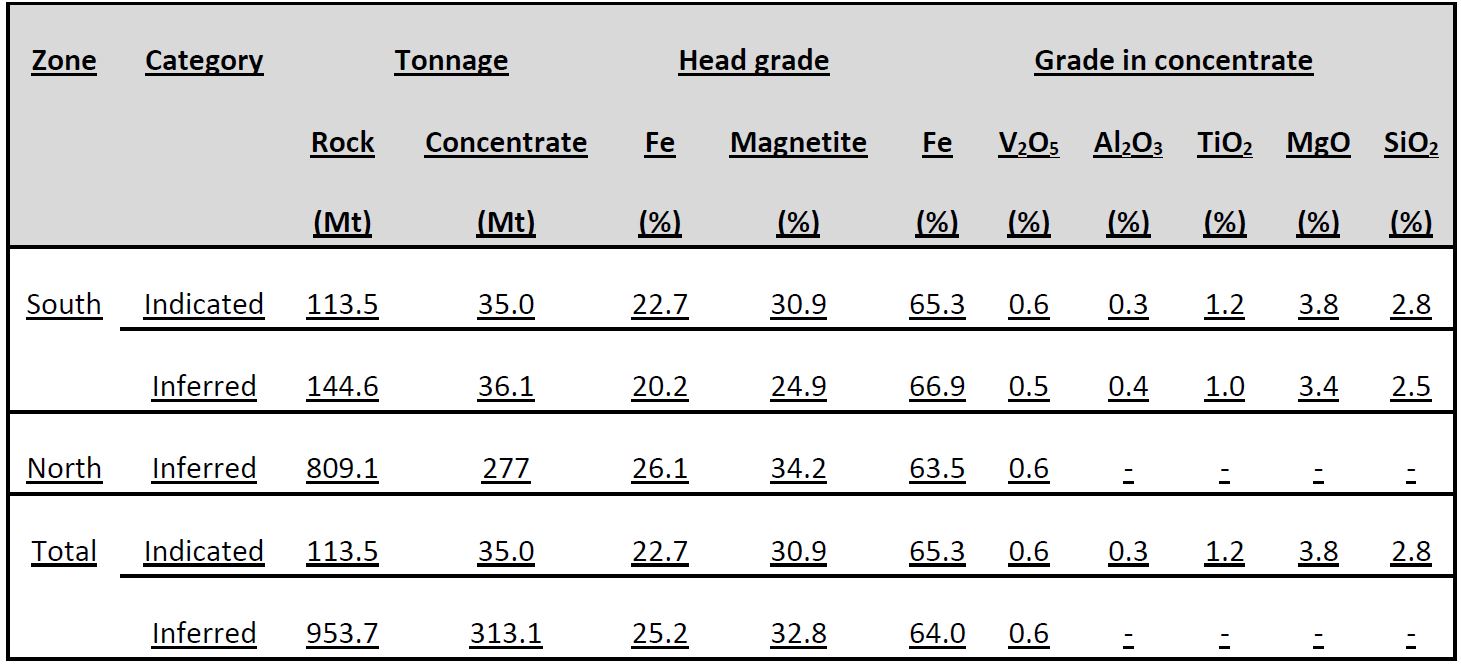

Total Inferred Resources for both the North Zone and South Zone are estimated at 953.7 Mt grading 32.8% magnetite, with the potential to produce 313 Mt of magnetite concentrate grading 64% Fe and 0.6% vanadium pentoxide (V2O5).

Total Indicated Mineral Resources remain unchanged and are estimated to be 113.5 Mt grading 30.9% magnetite, with the potential to produce 35.0 Mt of magnetite concentrate grading 65.3% Fe and 0.6% V2O5. Indicated Mineral Resources have only been estimated at the South Zone

The Mineral Resource Estimate is prepared in accordance with National Instrument 43-101 – Standards for Disclosure for mineral Projects by CSA Global Consultants Canada Limited with an effective date of June 25, 2021.

The Mont Sorcier iron ore deposit has two zones, known as the North Zone and the South Zone. The North Zone is estimated to hold Inferred Mineral Resources of 809.1 Mt grading 34.2% magnetite, with potential to produce 277 Mt of magnetite concentrate grading 63.5% Fe and 0.6% V2O5. This represents an increase of 432 Mt of Inferred Mineral Resource in the North Zone. The South Zone is unchanged and it is estimated to host 113.5 Mt of Indicated Mineral Resources grading 30.1% magnetite, with potential to produce 35.0 million tonnes of concentrate grading 65.3% Fe and 0.60% V2O5, and with low TiO2 (1.2%) in the magnetite concentrate. The South Zone is estimated to hold additional Inferred Mineral Resources of 144.6 Mt grading 24.9% magnetite, with potential to produce 36.1 Mt of concentrate grading 66.9% Fe and 0.50% V2O5.

Recent metallurgical testwork to assess concentrate grades has used the Davis Tube Test (DTT) method, which is a magnetic separation test on a small 50-gram portion of crushed sample preparation. Magnetic separation is expected to be more efficient when scaled up to larger samples and during production as indicated in historical testwork

Sign up for our newsletter